|

TYC 150246A

|

|

$86.99

Price

|

$0.00

Core

|

+ Sold in packs of 1x1

Pack

|

$86.99

Total

|

|

|

|

|

|

| The float arm (where pictured) may ship detached to prevent damage in transit. To connect, simply snap the wire end into the sender hole. |

| TYC 150246A Specifications |

|---|

| Connector Pins Qty On Main Connector | 4 Pins | | Fuel Level Sensor Resitance Range | 70-395 | | Fuel Tube Connection Type | Hose Camp | | GPH (Gallons Per Hour Flow) | 49.5-55.7 | | Maximum Air Pressure | 72.5-87 | | Strainer Included | Yes |

|

|

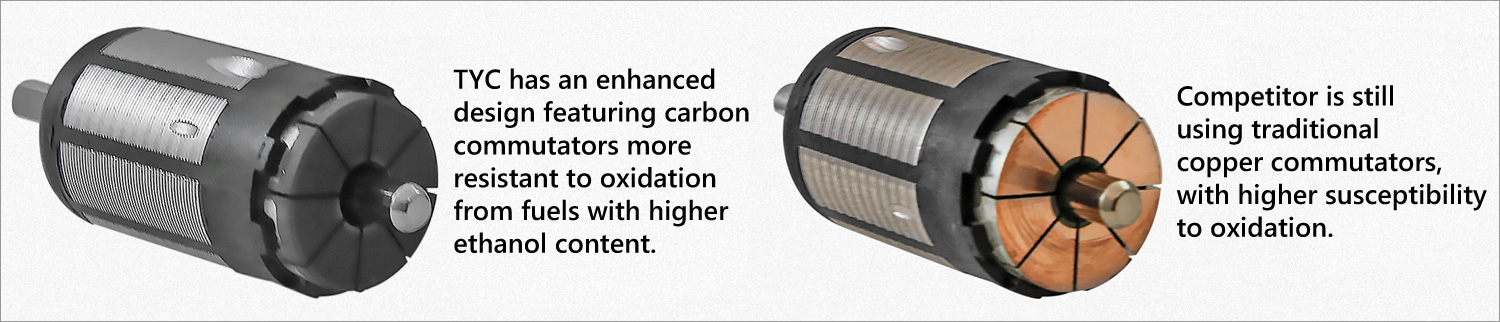

TYC's Fuel Pump & Housing Assemblies feature an upgraded design that utilizes premium components to best handle modern fuels. TYC has updated all their fuel pump modules to use carbon (instead of copper) commutators. This change allows TYC Fuel Pumps to smoothly operate with flex fuel blends up to E85 (85% ethanol).

Durability: Carbon's melting point is 3X greater than copper. This allows carbon brushes to wear more evenly, reduce sparking, and minimize damage to the conductive metal segments of the electric pump.

Smooth Operation: Carbon is a softer compound compared to copper, resulting in quieter operation. Additionally, carbon's inherent self lubrication properties and dry running capability help the pump to stay cool during operation.

Increased Efficiency: Carbon actually becomes more conductive as temperatures climb. This means less electrical current is needed to maintain optimum fuel flow as the pump warms up; saving energy and reducing the temperature of wiring and other components.

Benefits of Purchasing a Fuel Pump & Housing Assembly Purchasing just the fuel pump is less expensive up-front, but a complete Fuel Pump & Housing Assembly provides added benefits:

- Extend Service Life: New strainer(s), hoses, sensors and other components help resolve problems that could be caused by more than just the pump.

- Reduce Install Time: Since you don't have to disassemble the housing, which could lead to damage, replacement becomes a simple swap, dramatically reducing installation time.

- Save Money: The cost of the assembly is often cheaper than buying the components individually, and means you only have to do the job once.

Prevent Premature Fuel Pump Failure Preventing premature fuel pump failure is far less expensive and time consuming than continuing to replace the pump. There are three common causes for premature fuel pump failure:

| ELECTRICAL ISSUES |

Poor electrical connections will mimic symptoms of a failed pump, sometimes resulting in unnecessary replacement. Before replacing the pump:

- Use a Fuel System Tester to test pump pressure is within expected range

- Use an Electrical Tester to test for bad wiring, burnt or corroded connectors

- Check / Replace faulty Fuse(s) and Relay

BEFORE REPLACEMENT |

| FUEL CONTAMINATION |

Dirt, rust or debris in the fuel can clog strainers and stick to internal pump components. When replacing the pump:

- Replace Fuel Filter or Fuel Strainer

- Empty and clean the tank with Fuel Tank Cleaner

- Fill tank with fresh, uncontaminated fuel of appropriate grade

DURING REPLACEMENT |

| PUMP DAMAGE / OVERHEATING |

Running low on gas causes your fuel to heat up quicker, and your pump to work harder. After replacing the pump:

- Maintain at least 1/4 tank of fuel and use a Fuel Additive / Conditioner to keep pump cool and lubricated

- If vehicle is stored without use, drain tank to prevent pump corrosion from fuel oxidation

AFTER REPLACEMENT |

|

| OEM / Interchange Numbers: 16146766942 |

TYC Warranty Information:Limited Lifetime for non-commercial useWarranty Details |

|